Shipbuilding

HD Hyundai Heavy Industries Shipbuilding Business Unit

Leading the global shipbuilding industry

with world-leading

ship construction

technology

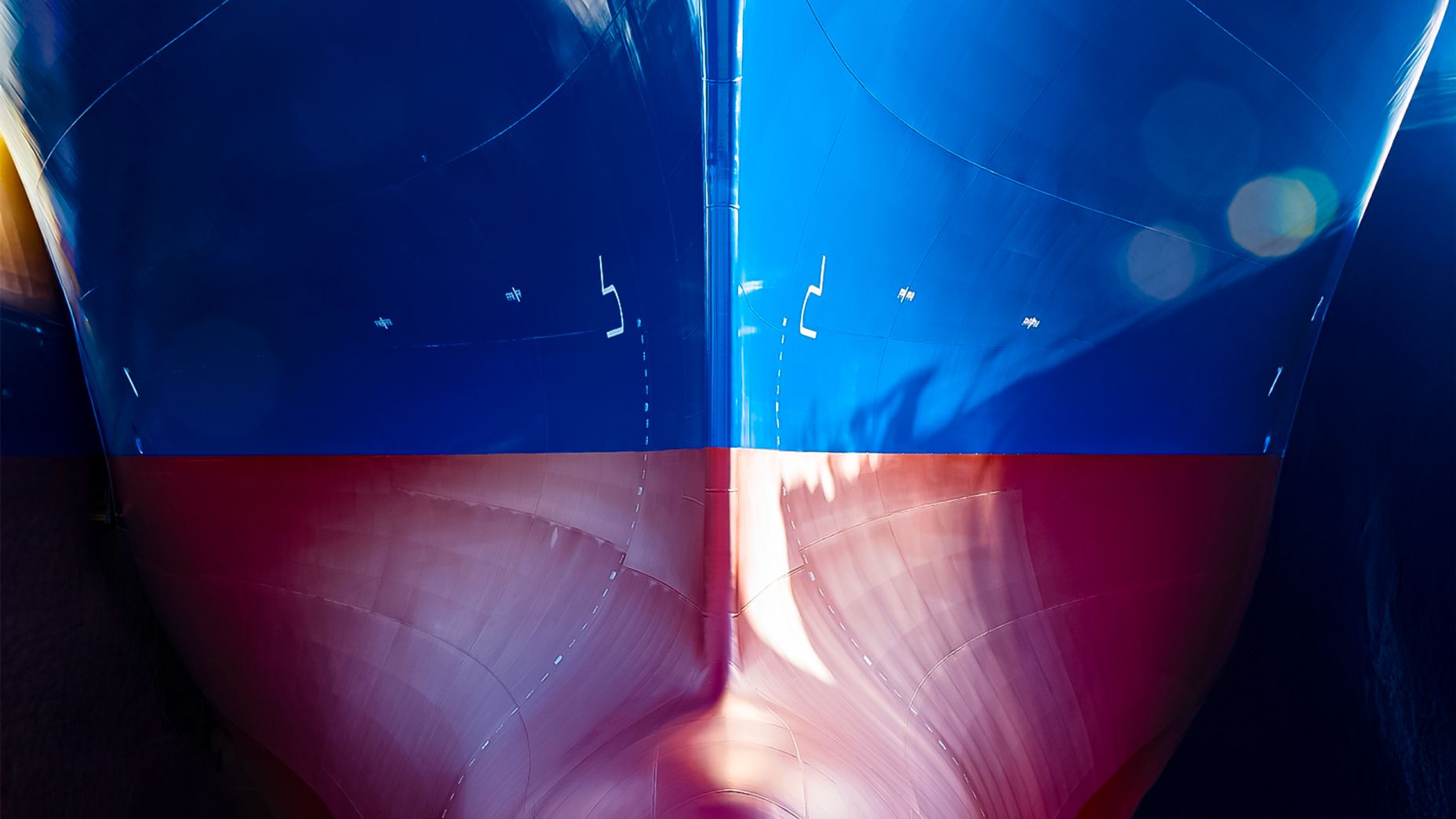

Shipbuilding

We are at the epicenter of the world shipbuilding industry, distinguished by our record of having the world's largest number of ship construction.

Since being ranked first in the world for shipbuilding orders and construction volume in 1983, the Shipbuilding Business Unit has remained at the forefront of the global industry. It stands as a core division of HD Hyundai Heavy Industries."Shipbuiliding Business Unit of HHI, since being ranked first in the world for shipbuilding orders and volume in 1983, has remained at the forefront of the global industry. It stands as a core division of HHI.

In March 1972, HHI began construction of a shipyard in what was then barren Mipo Bay, Ulsan. In just two years and three months, the company completed the world’s largest shipyard and successfully built a 260,000-ton VLCC ordered by Greece. This achievement marked the first time in history that a shipyard was completed alongside the delivery of a vessel — a modern milestone that makes us a living witness to the evolution of the global shipbuilding industry.

A Global Shipbuilding Leader

The Shipbuilding Business Unit operates 10 large dry docks and 9 Goliath cranes. Supported by state-of-the-art production systems, skilled human resources, and advanced shipbuilding technology, the unit constructs around 50 large vessels annually—including LNG and LPG carriers, drillships, methanol fueled containerships, crude oil carriers, and car carriers.

As of now, the Shipbuilding Business Unit has delivered over 2,400 vessels to 350 shipowners across 51 countries. In 2012, it became the first in the world to surpass 100 million gross tons in shipbuilding volume, followed by another global milestone in 2015: “the completion of 2,000 ships.”

Drawing on our long-standing reputation in the global shipbuilding market, we will continue to drive technological innovation and strengthen our competitiveness. We are committed to proactively responding to the growing demand for green, energy-efficient vessels and specialized offshore ships, thereby further solidifying our status as the world’s premier shipyard.

Main Products

- General Merchant Ships container ships, LNG carriers, LNG-FSRU ⑴ , LPG carriers, LEG carriers, Tankers, petrochemical product carriers, bulk carriers, car carriers, Ro-Pax, RO-RO, LNG bunkering vessels

- Special Merchant Ships Drillships, semi-submersible drilling rigs, offshore support vessels (OSV) ⑵

- FSRU : Floating, Storage, Re-gasification Unit

- OSV : Offshore Support Vessel

Main Products

CNTR - 16,200 TEU CLASS METHANOL DUAL FUEL CONTAINER CARRIER

Specifications

- LBP 336.78m

- Breadth 53.50m

- Depth 33.20m

Characteristics

- A vessel for MAERSK, a global leader in container shipping

- Cargo Capacity Can load approximately 16,000 containers (TEU)

- Funnel Arrangement Funnels are placed at both the forward crew quarters and the stern to maximize container capacity and improve operational efficiency.

- Eco-Friendly Design Eco-friendly design features include high-efficiency technologies such as Pre Swirl Duct, Rudder with Bulb, and Hull Form Optimization.

- Use of eco-friendly fuel Using methanol—an eco-friendly fuel—to reduce CO₂ emissions.

- Methanol Fuel Supply System (Hi-LGAS) Equipped with Hi-LGAS, an in-house methanol fuel supply system developed by HD Hyundai Heavy Industries.

FSRU - 170,000m³ LNG FLOATING STORAGE REGASIFICATION UNIT

Specifications

- LBP 282.00m

- Breadth 46.00m

- Depth 25.60m

Characteristics

- A hull form offering high flexibility for operating in the world’s main ports, terminals, and sites.

- Multi-Purpose Vessel Specifications of a multi-purpose vessel designed for LNG carrier capability

- Equipped with a GTT MARK III Membrane cargo tank system.

- Eco-Friendly Design Eco-friendly design features include high-efficiency technologies such as Rudder Bulb and Hi-Fin

LPG - 88,000m³ CLASS LPG DUAL FUEL LPG CARRIER

Specifications

- LBP 223.45m

- Breadth 32.25m

- Depth 23.85m

Characteristics

- Construction of Seven Sister Ships Seven sister ships were built to transport LPG along the Houston-Panama-Asia route.

- 88,000m³ in size 88,000m³ LPG (liquefied petroleum gas) carrier

- Eco-Friendly Design Eco-friendly design features include high-efficiency technologies such as Hi-PSD, Hi Rudder Bulb RS, Hi-Fin, and Hull Form Optimization.

- Compatible with Alternative Fuels The vessel can use LPG—a low-sulfur, low-carbon fuel—as an alternative fuel, making it well-suited to meet environmental regulations.

VLEC - 98,000m³ CLASS ETHANE/LPG CARRIER (D/F)

Specifications

- LBP 224.60m

- Breadth 36.60m

- Depth 18.48m

Characteristics

- Construction of Seven Sister Ships A total of seven sister ships were built to transport ethane from the STL plant on the US Gulf Coast to Lianyungang in China.

- Enhanced Energy Efficiency and Operational Efficiency To enhance both energy and operational efficiency, the ship is equipped with Hi-PSD, Hi-Rudder, Hi-Fin, and Hyundai-ISS (Integrated Smart Ship Solution).

- Reduced CO₂ Emissions Using ethane as an alternative fuel helps reduce CO₂ emissions.

- Selected as World Class Ships in 2023

VLCC - 300,000 DWT CLASS CRUDE OIL CARRIER

Specifications

- LBP 318.00m

- Breadth 60.00m

- Depth 29.60m

Characteristics

- Equipped with energy reduction technologies. With optimized hull design and a range of energy-saving solutions, the vessel achieves outstanding performance beyond industry standards.

- Eco-Friendly Design Eco-friendly design features include high-efficiency technologies such as Hi-PSD and Rudder Bulb with Skirt.

- EGCS-Ready Design EGCS-ready design features are incorporated to allow future installation of the Exhaust Gas Cleaning System (EGCS).

- Enhanced Operational Efficiency Operational efficiency is enhanced through the installation of Hyundai-ISS (Integrated Smart Ship Solution).

Gallery